The Benefits |

|

|

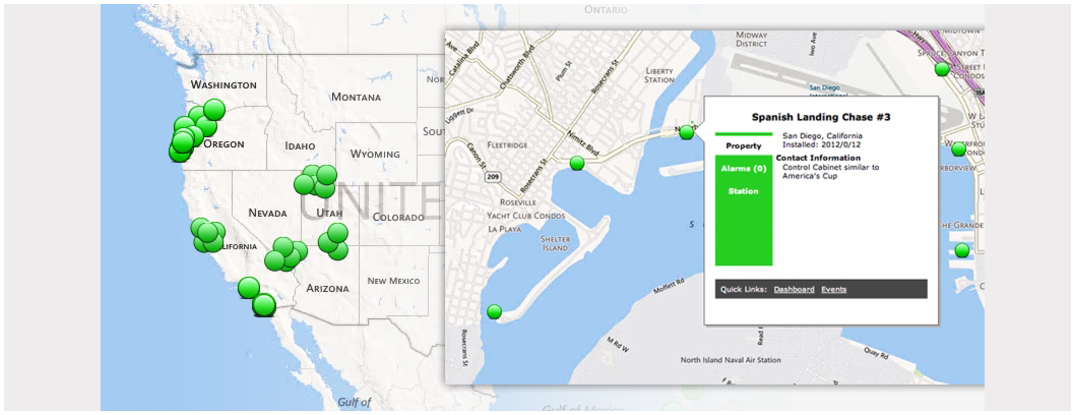

The MS1 transmits data to a web-based software application, which is only accessible by assigned subscribers with secure logins. The software allows subscribers to monitor and manage all monitored equipment. Subscribers can manage multiple Pumps, Floating Restrooms or other Equipment through a single webpage.

Each MS1 location is identified on the map with a real-time status dot. A green dot signifies the device is operating normally and a red dot represents an alarm. To view data for a particular pump, mouse-over the dot and a dialog box will appear that shows details of the site and current status. Click on the “manage” link to open the dashboard. The user may also navigate to any asset, or to organization and system levels, by clicking on the desired link within the navigation bar which is visible at all times on the left of the display.