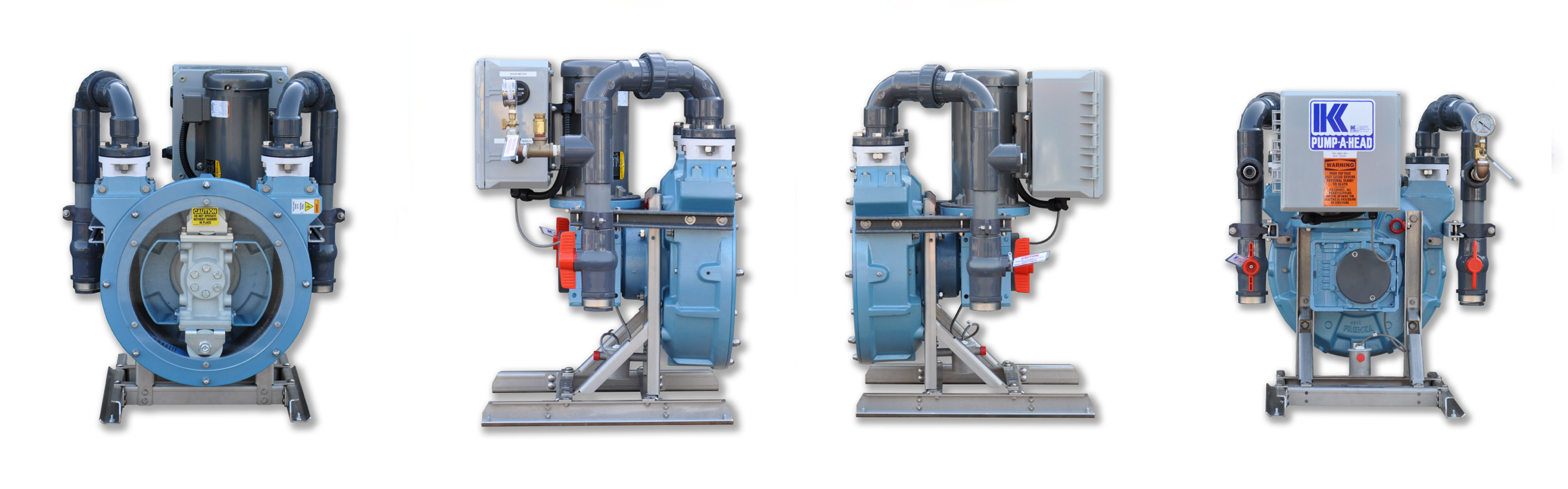

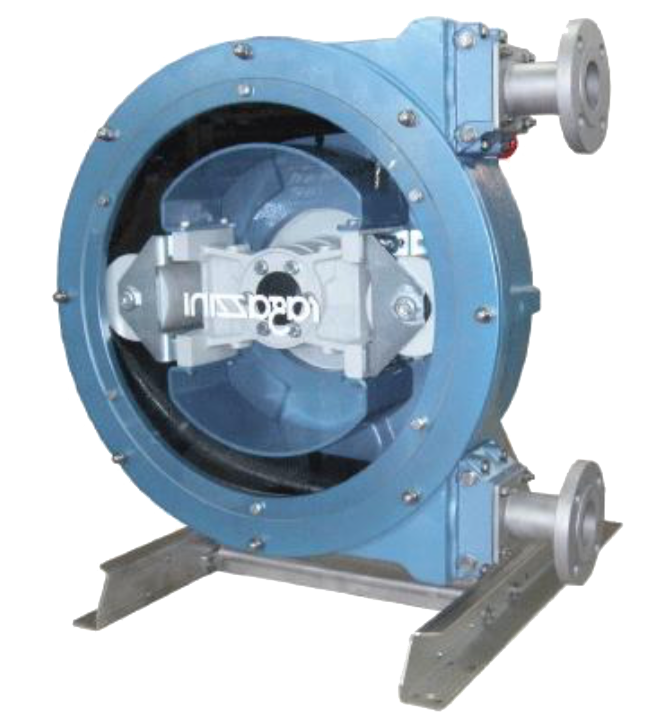

900-Series Peristaltic Pumps

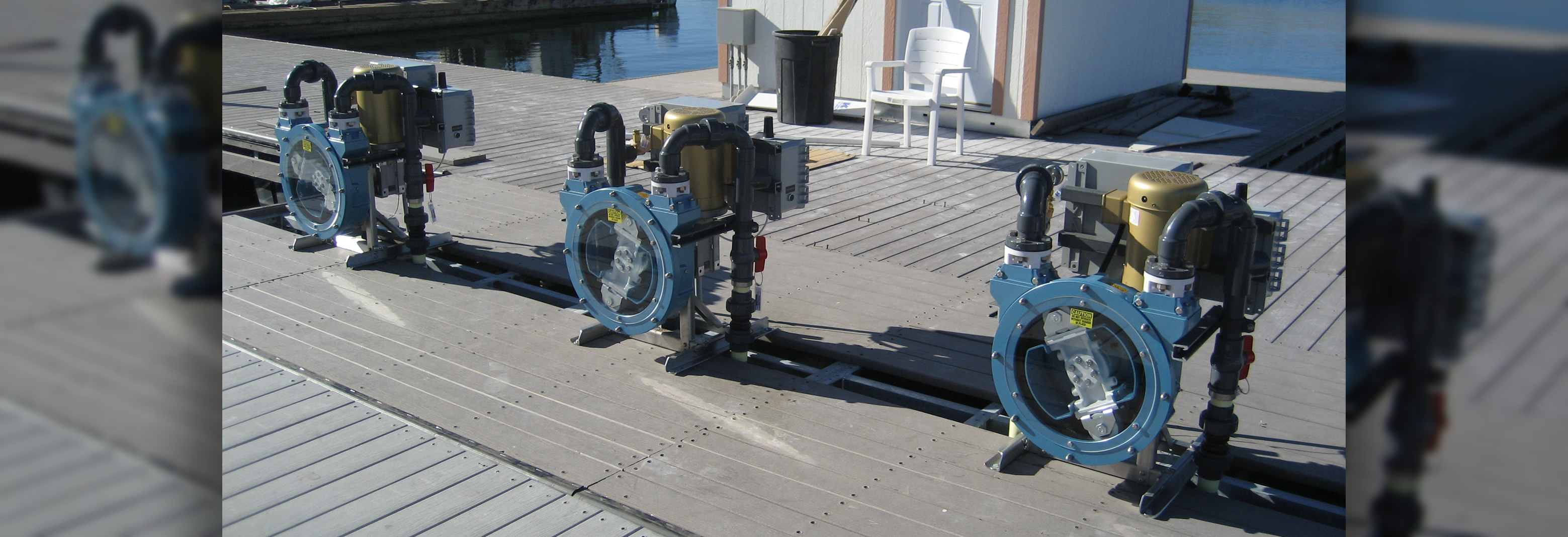

Keco’s Peristaltic Pumps have revolutionized the Marine PumpOut industry. With an emphasis on simplicity, Keco’s 900- Series Peristaltic pumps are Intuitive and mechanically simple. The Peristaltic concept relies on fluid being squeezed through a tubular element installed within the pump housing. As the tube is compressed pressure is created, and when the tube returns to its normally open shape suction is created.

Keco’s design utilizes Roller Technology to compress the internal hose helping eliminate friction and extending hose life. Keco’s Peristaltic pumps feature a valve-less design eliminating disruptive clogs and reducing pump harmonics (noise). Keco’s Peristaltic Pumps can generate a near perfect Vacuum (29”Hg) and create remarkable pressures (240psi) making them ideal for almost any application. With an Extensive Range of Peristaltic pumps, you can rely on the experts at Keco to assist with pump sizing and selection.

Request Info

*Model 900_M40_3HP Shown

Modular Design

While Keco’s Peristaltic Pumps Are Extremely Rugged, being Realistic about Maintenance and Serviceability is a must. For this Reason, Keco has taken a Modular approach to simplify maintenance and reduce down-time during unplanned failure. Keco’s modular design allows key components to be exchanged eliminating timely repairs and keeping customers happy.

Leak Detection Shutdown

Getting the most out of your Internal Peristaltic Hose is a must. Containing and Eliminating hazardous fallout is equally important. All Keco Peristaltic pumps are equipped with a Leak Detector designed to Contain and Deactivate the Pump upon internal hose failure. This simple yet effective safety feature provides peace-of-mind and round the clock protection.

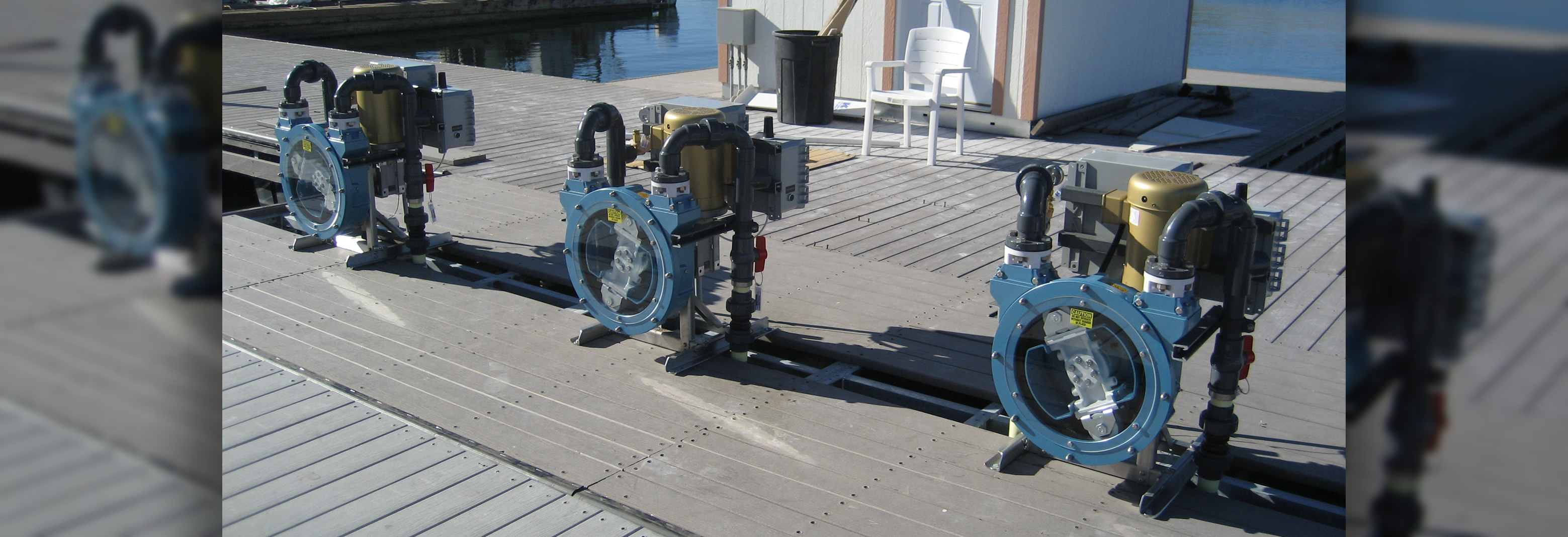

Clear Viewing Window

Keco’s Peristaltic Pumps Are Equipped with an Iconic and Functional Clear Viewing window. This large viewing window allows for general inspection without the need for tools. This Hands Off approach enables service personnel to get a thorough glance into the pumps inner mechanics. Within seconds a potential problem can be diagnosed helping reduce downtime and taking out the guesswork.

Quality Hoses

Keco’s Peristaltic Internal Hoses are designed to withstand the harshest conditions. Reinforced with layers of Nylon threads these rugged internal hoses can handle foreign solids and fluctuating temperatures. Keco’s Peristaltic Hoses are machined to precision and are serialized for added quality control.

Extended Hose Life

Keco’s conservative approach to Pump speed allows the internal Peristaltic hose to make it the extra mile. Just like a car tire, each revolution of the Peristaltic pump adds wear and tear to the internal hose. Running the Peristaltic pump at a slower RPM not only saves on costly repairs, it also puts less strain on key mechanical components helping extend service life.

Roller Technology

Keco believes in the philosophy that less is more. By using permanently sealed Rollers to compress the internal Peristaltic Hose, Keco is able to eliminate unwanted friction resulting in longer hose life. Keco’s free spinning rollers eliminate the need for an oil filled pump cavity creating a more sanitary and maintenance friendly environment. The rollers can be easily removed for winterization or shimmed for increased pressure.

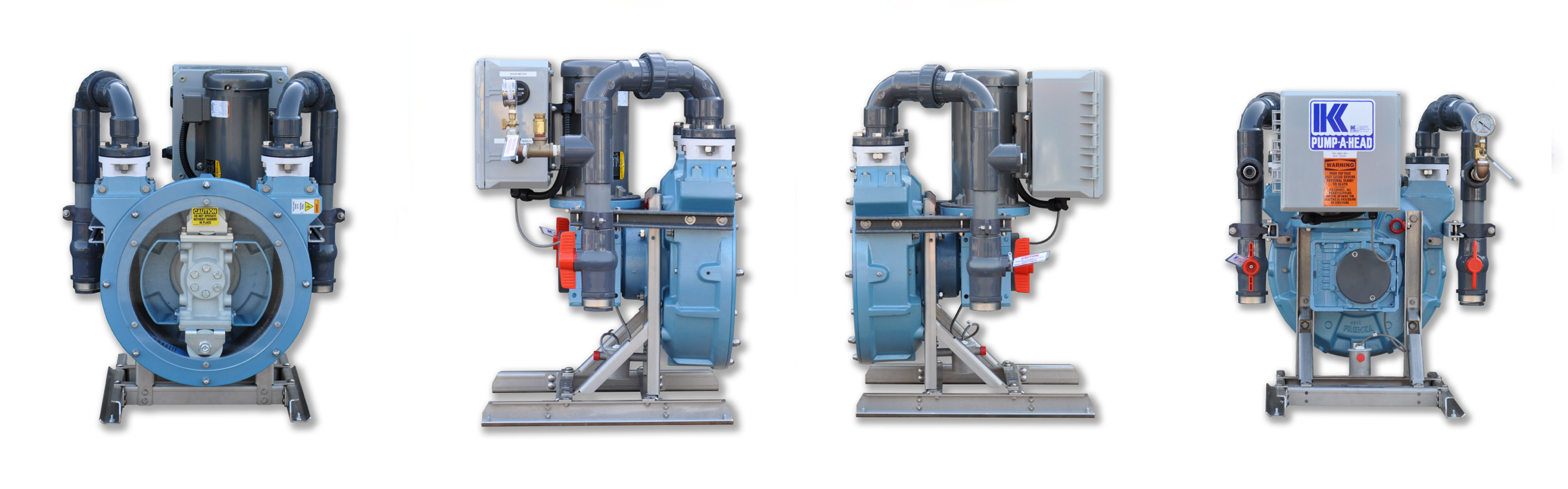

UL Panels / Super Efficiency Motors

Keco believes Going Green shouldn’t be an option, but rather the standard. Instead of following in someone’s footsteps, Keco is taking the lead by equipping all Peristaltic Pumps with Super Efficiency motors. Not only does Keco Strive to be the leader in efficiency, we believe manufacturing to National Standards is equally important. Outfitting all Peristaltic Pumps with UL-Listed Controllers provides consumer confidence and allows our customers to remain in compliance.

Factory Installed Plumbing

Everyone knows having the right tool can make a job easier. Keco has taken this to heart by outfitting all 900-Series Pumps with pre-assembled plumbing manifolds. These manifolds come equipped with Isolation Valves and Gauges for Post Installation Testing, Servicing and Troubleshooting. These manifolds not only streamline installation they help minimize downtime and simplify post installation support.

The Features

- Large Clear Viewing Window

- Direct Drive Gearbox

- Leak Detection Shutdown

- Stainless Steel Pump Frame

- Tripple Reinforced Peristaltic Hose

- Dry Pump Cavity

- Valveless & Sealess Design

- 3-Year Standard Warranty